Gluing technology for the automotive industry

Automotive

The areas of adhesive application in the automotive industry are as versatile as the gluing technologies themselves. Gluing is increasingly replacing conventional car production techniques such as welding, riveting and screwing. It not only increases safety, but also simplifies many work processes and therefore improves economic efficiency.

Kaletech supplies powerful systems for the application of hot-melt, dispersion, and reactive adhesives for body and interior components, assembled parts, rear-view mirrors, roof linings, damping and thermal insulation parts, seat covers, headlamps and rear lamps.

Contact us. We will design a tailor-made adhesive application system and provide training in its use. You can rely on our service, or try the technology in advance in our rental shop.

Typical gluing applications in the automotive industry

- Body assembly

- Interior assembly

- Headlamp and light sealing

- Wheel cover assembly

- Vehicle glass gluing

- Sound and thermal insulation

- Car battery production

- Assembly of sand cores and moulds in the foundry using PA

- Car logo gluing

- Lock gluing

What we have been able to solve

Click to view the details of each case study

Application of hot-melt adhesive for rear car seats

The control unit communicates with an industrial robot and adhesive is applied in the precise quantity and in the desired locations.

Automatic measurement of hot-melt adhesive quantity

Thanks to the automatic adhesive application management system, we made it possible for our customer to save €35,000 a year on rejects and material.

A universal application head allows variable production

The technical solution allows the customer to produce several products on one line.

Assignment

A request from a leading car seat manufacturer involved the delivery of adhesive application technology capable of collaborating with an industrial robot in order to make the production automatic.

Solution

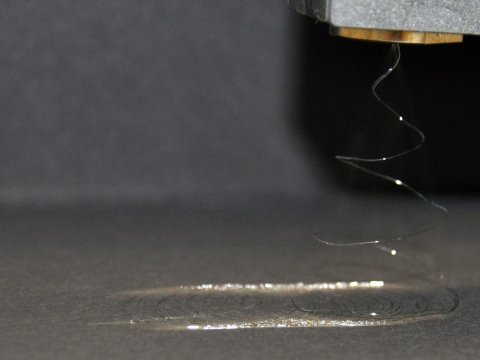

The application head applies a spray coating of hot-melt adhesive. Depending on the movement and position of the industrial robot, it deliberately omits the places above holes.

Results

The result is a fully automated work station with the precise application of the desired layer of adhesive in the desired locations.

Assignment

A leading automotive upholstery manufacturer contacted Kaletech with a request for automated measurement of adhesive application for upholstery for car door panels. The customer's main requirement was to keep the adhesive deposit between two layers of upholstery materials constant.

Solution

The solution consisted of the use of a travelling thermal camera which scans and measures the adhesive coating thickness. It evaluates and gives a warning if the layer breaches the limits or indicates future irregularities and produces a report for quality control. The device has the possibility to change the gluing parameters on-line.

Results

The new solution is more efficient from the point of view of adhesive consumption and thanks to the automated measurement system, the quality of uniformity of its application is monitored continuously. Our customer saves €27,000 per year on rejects and €8,500 on adhesive consumption.

Assignment

The customer's requirement was to deliver gluing technology which would allow them to change the parameters and gluing width according to the needs of individual products.

Solution

The solution was to design a unique application head with 78 modules and a blade that allows intermittent adhesive application.

Results

The customer can set the parameters and width of gluing for individual products without stopping production for complicated adjustment of the machine.