Gluing technology for the printing industry

Printing

Kaletech s.r.o. brings comprehensive systems for processing and applying thermoplastic hot-melt adhesives, reactive hot-melt adhesives, cold-applied adhesives and any plasticisers used in the printing industry.

In particular, the solutions include adhesive pre-melting for bookbinding (hardback & paperback), web printing, advertising distribution or other processing of printed materials and production of envelopes.

Contact us. We will design a tailor-made adhesive application system for the printing industry for you and provide training in its use. You can rely on our service, or try the technology in advance in our rental shop.

Typical applications in the printing industry

- Book spine gluing

- Side gluing

- Fusion for roller applicators

- Photobook Application

- Sticking advertising materials

- Gluing newspapers and magazines

- Paper adjustment before assembling the pages

- Putting together newspapers and magazines

- Backing using hot-melt adhesive

- “In-plate” gluing

- Gluing windows for envelopes

- Backing with PSA adhesives

- Cold side gluing of envelopes

What we have been able to solve

Click to view the details of each case study

Commissioning of textbook production for the Ministry of Education in Kuwait

Thanks to the timely intervention of our expert, our customer managed to maintain a key customer of his affiliate on the Arabian Peninsula.

Assignment

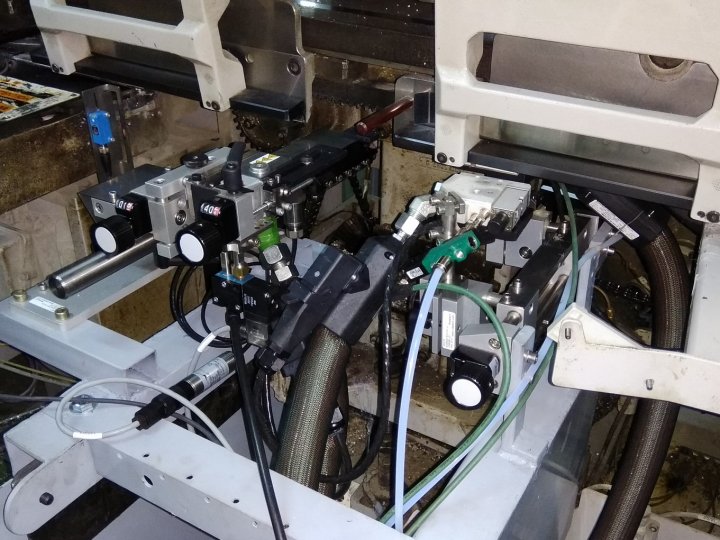

Thanks to the successful implementation of a project in Sydney, Australia, our company was presented with the requirement to commission the printing process for the production of textbooks in Kuwait. The problem this time was not only in the correct application of adhesive, but in the production settings. The machines were more than 50 years old and the operators lacked both knowledge and experience.

Solution

With regard to the type of paper, it was necessary to set the book back milling operation properly. The next step was the choice of the correct adhesive, reactive PUR in this case. Adhesive must be applied in a layer with correct and constant thickness. The last step was to create a transport path on which the adhesive would have enough time to cure, and the binding would not disintegrate during handling.

Results

Despite the short time set out by the Kuwaiti Government for commissioning, the language and cultural barriers and obsolete production technology, the production was eventually launched in the required quality. The final product was approved by the Ministry of Education, which represents 90% of our customer's sales, so is a key customer for them.