Examples of implementations and case studies

Gluing of ground AKU bricks with soundproofing

Saving time, space and production costs by choosing a better adhesive and process optimisation

Application of spray gluing for medical material

The universal solution of the technology allows the production of a large number of product variants.

Commissioning of textbook production for the Ministry of Education in Kuwait

Thanks to the timely intervention of our expert, our customer managed to maintain a key customer of his affiliate on the Arabian Peninsula.

Assignment

One of the largest Czech manufacturers of building materials presented Kaletech with the requirement to glue sound insulation wool between two parts of acoustic bricks. This was an improvement of already existing production.

Solution

Kaletech offered a solution in the form of replacing the PUR foam with a hot-melt adhesive and process optimisation. In terms of functionality, the hot-melt adhesive was as suitable as the PUR foam.

Results

The result was rapid acceleration of production of one piece, thanks to faster drying of the adhesive. In addition to the time for production of one piece, the customer also saved an area in the production hall thanks to the removal of several dozen metres of belt for drying.

Assignment

VA manufacturer of medical material for operating rooms contacted Kaletech requiring a solution for the gluing of impermeable membranes and non-woven fabric.

Solution

The solution consisted of the use of a spray adhesive application. It was necessary to set an appropriate layer of adhesive, which is applied to the patient's skin with optimal force, while guaranteeing the impermeability of the material. Fixed application heads are switched on depending on the desired quantity of the product.

Results

On a complex production line it is possible to produce up to 86 different products using the same equipment.

Assignment

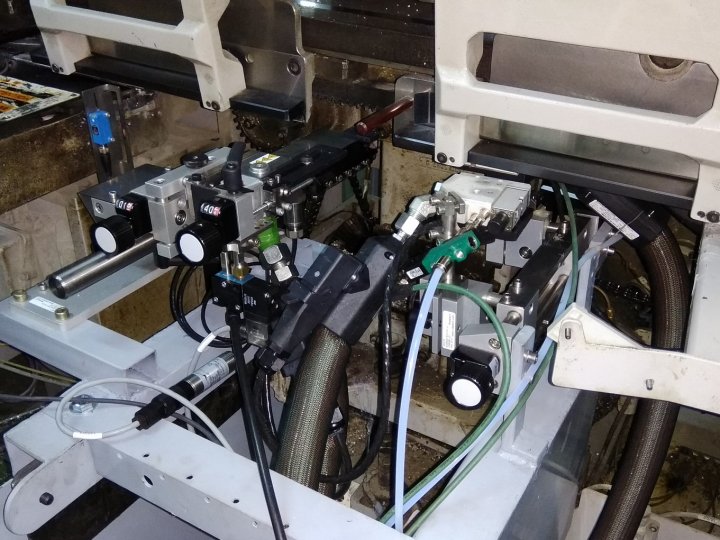

Thanks to the successful implementation of a project in Sydney, Australia, our company was presented with the requirement to commission the printing process for the production of textbooks in Kuwait. The problem this time was not only in the correct application of adhesive, but in the production settings. The machines were more than 50 years old and the operators lacked both knowledge and experience.

Solution

With regard to the type of paper, it was necessary to set the book back milling operation properly. The next step was the choice of the correct adhesive, reactive PUR in this case. Adhesive must be applied in a layer with correct and constant thickness. The last step was to create a transport path on which the adhesive would have enough time to cure, and the binding would not disintegrate during handling.

Results

Despite the short time set out by the Kuwaiti Government for commissioning, the language and cultural barriers and obsolete production technology, the production was eventually launched in the required quality. The final product was approved by the Ministry of Education, which represents 90% of our customer's sales, so is a key customer for them.